|

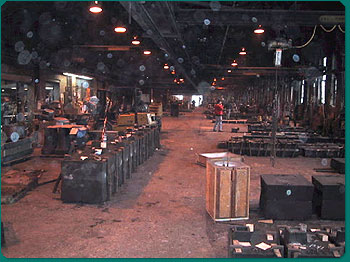

Pictured here is the main molding area at Fairmount Foundry.

Typical castings produced at Fairmount Foundry include pump housings, pressure vessels, valves, compressor parts, heat transfer equipment, and hard iron wear parts. |

We excel at providing solutions to tough casting problems. Our skilled workforce encompasses 100's of years of experience.

In order to provide our customers with the best possible product, Fairmount Foundry uses primarily no-bake molding. Additionally, traditional green sand molding is available.

The no-bake molding process provides better dimensional control, smoother surface finish, and a higher quality casting. |

|

|

Our in-house sprectrometer allows us to produce virtually any grade of iron and aluminum.

This technology allows us to produce standard, and/or "custom alloys", as specified by the individual customer. Material certifications can be kept at Fairmount, or forwarded to the customer as required. |

|

|

|